Any questions, please e-mail at support@xylotex.com

This item is currently listed on ebay.

The Price through ebay is $325.00 + $34.10 USPS Priority Mail Shipping & applicable taxes

To get this item with 1/2 OFF shipping, e-mail the above address so a Paypal Invoice can be made.

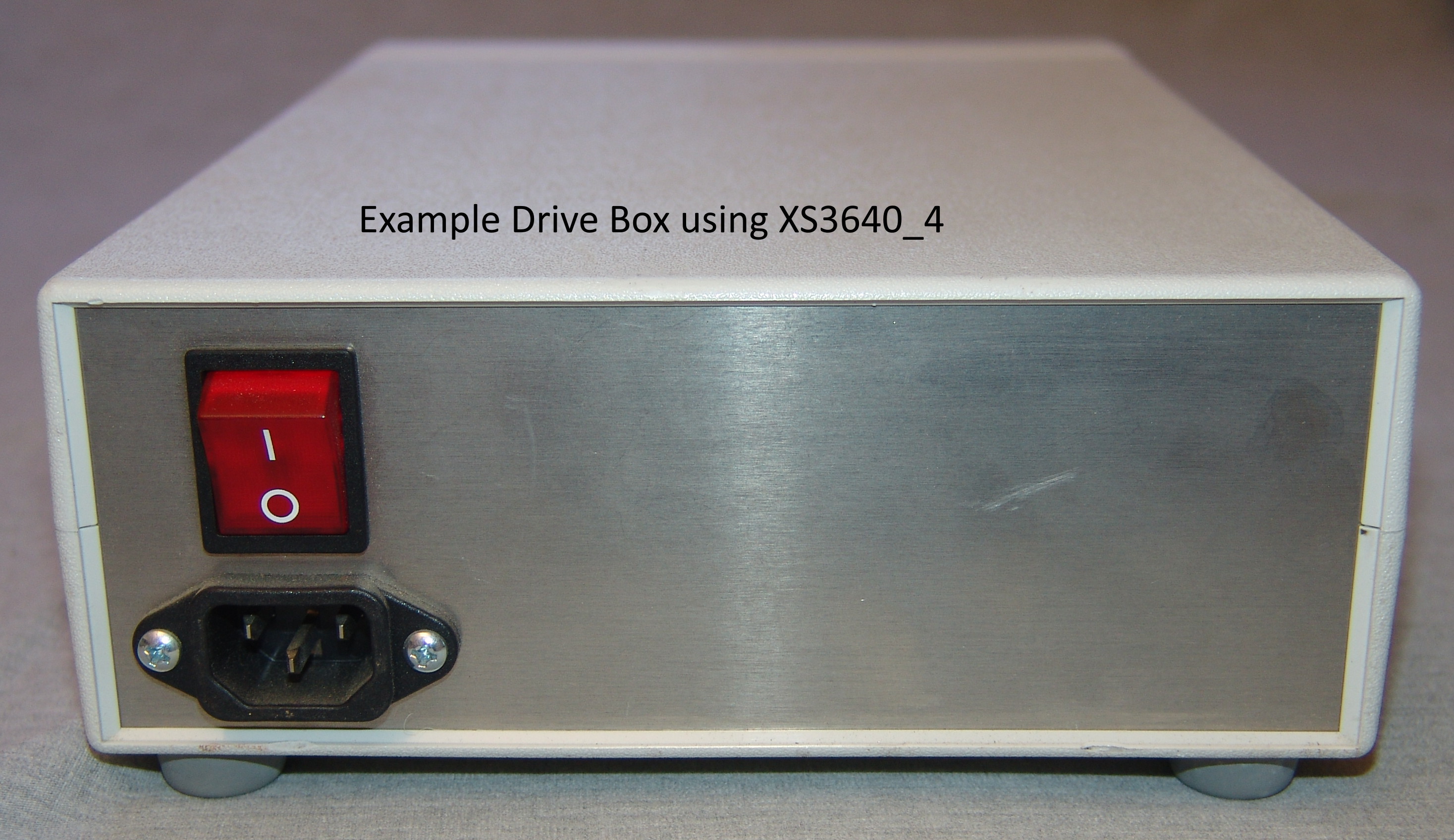

4 Axis Drive Box

- This is a complete, Ready-to-Run, Plug-and-Play Stepper System for small CNC systems like Sherline, Taig or small CNC wood routers.

- Can be used for 3 or 4 axis CNC Mills with a Rotary Axis or Gantry type CNC routers. The 4th axis use is not specifically required, will run with 3 motor just fine as well.

- Software use such as MachineKit, Mach3/4, LinuxCNC, UC100/300 should contact their respective user applications help. See below for specific information regarding the pinout for the drive box.

* 1/16th step (microstep) for smooth, precise motion.

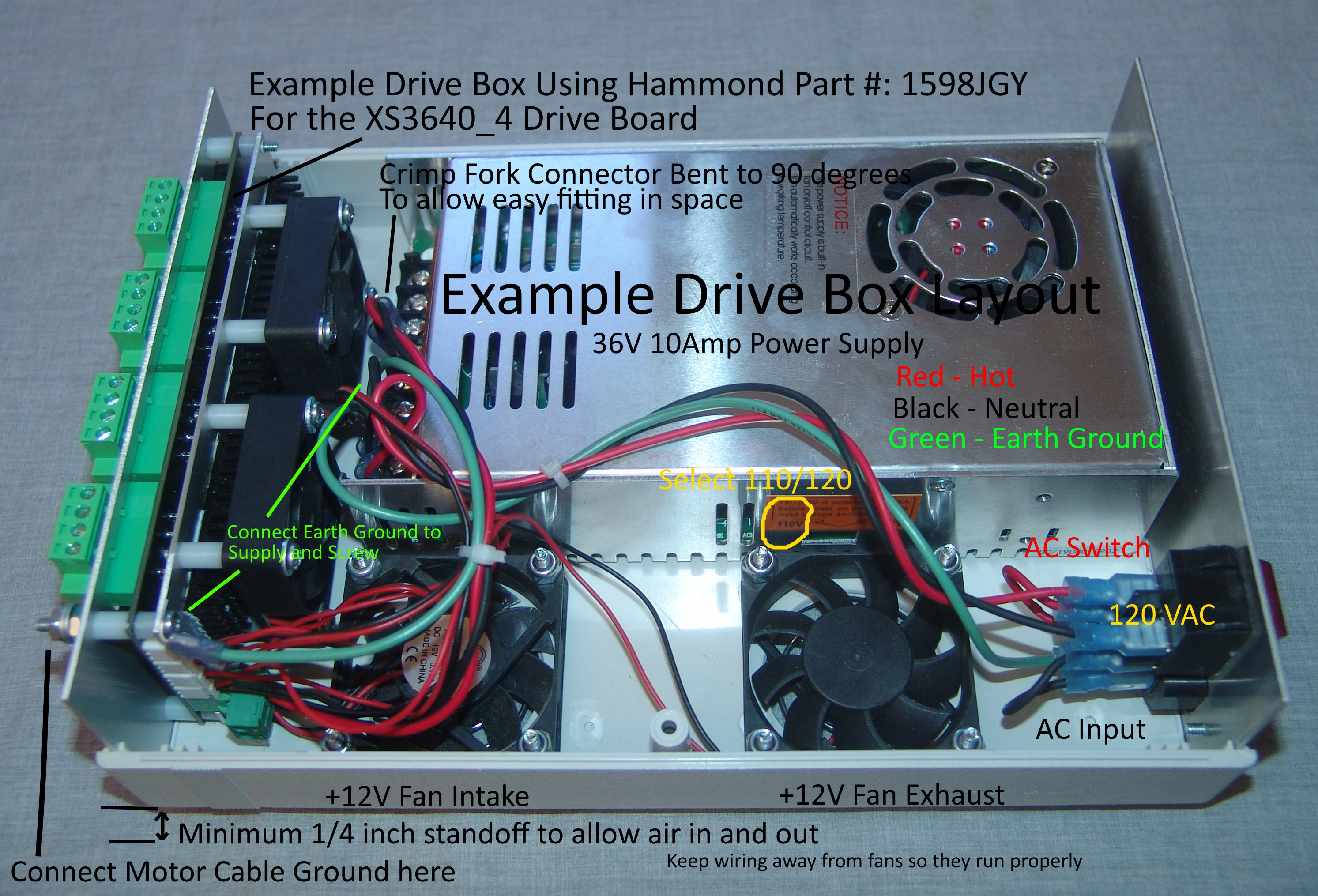

* Four Built-in Cooling Fans

* The 36V system gives faster top end speeds compared to lower voltage systems.

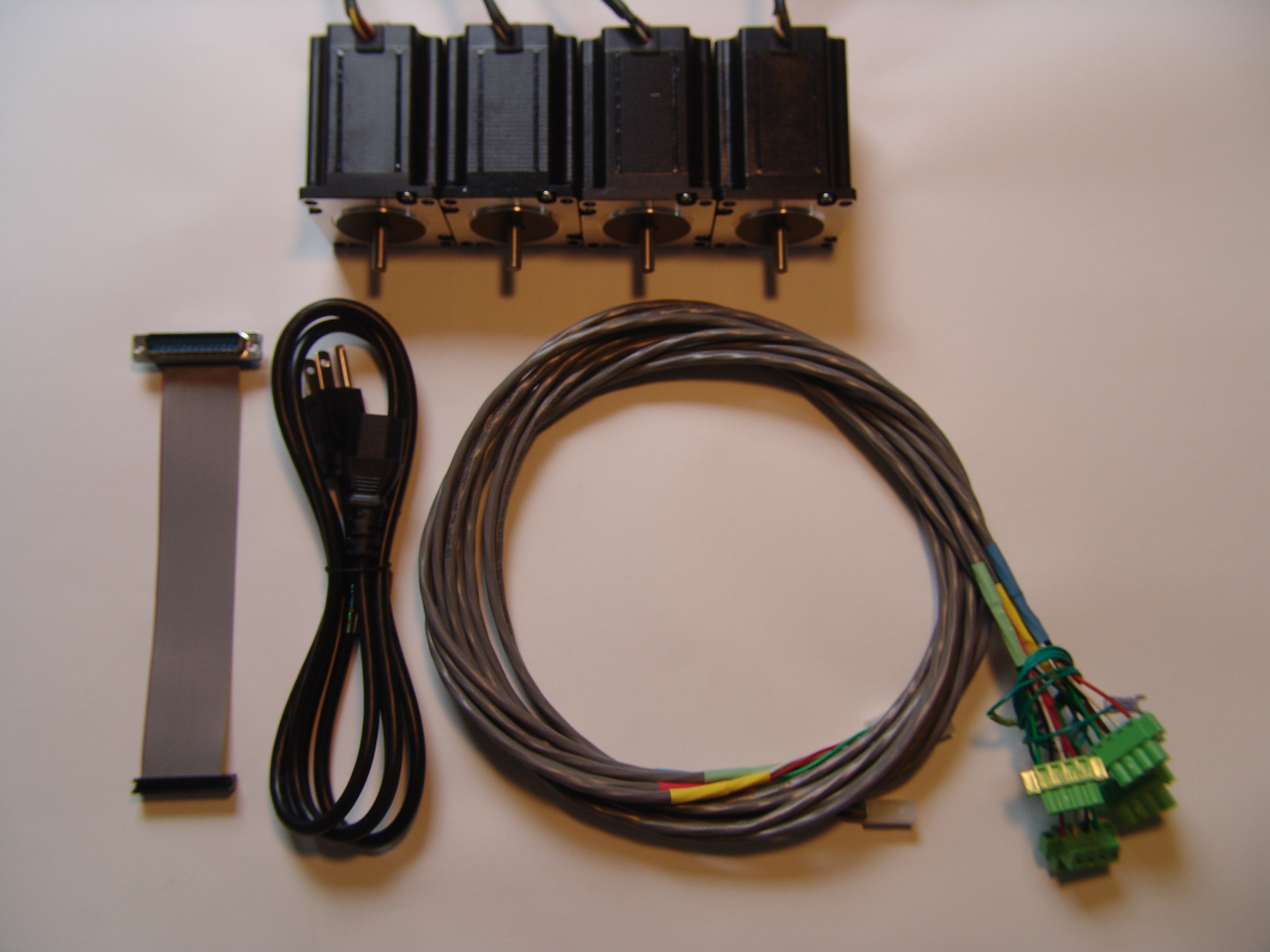

* (4) 269 oz.in Dual Shaft stepper motors

* (4) 6 foot motor cables with Drain Ground

* IEC 120VAC power Cord

* IDC26-DB25-M Signal Cable

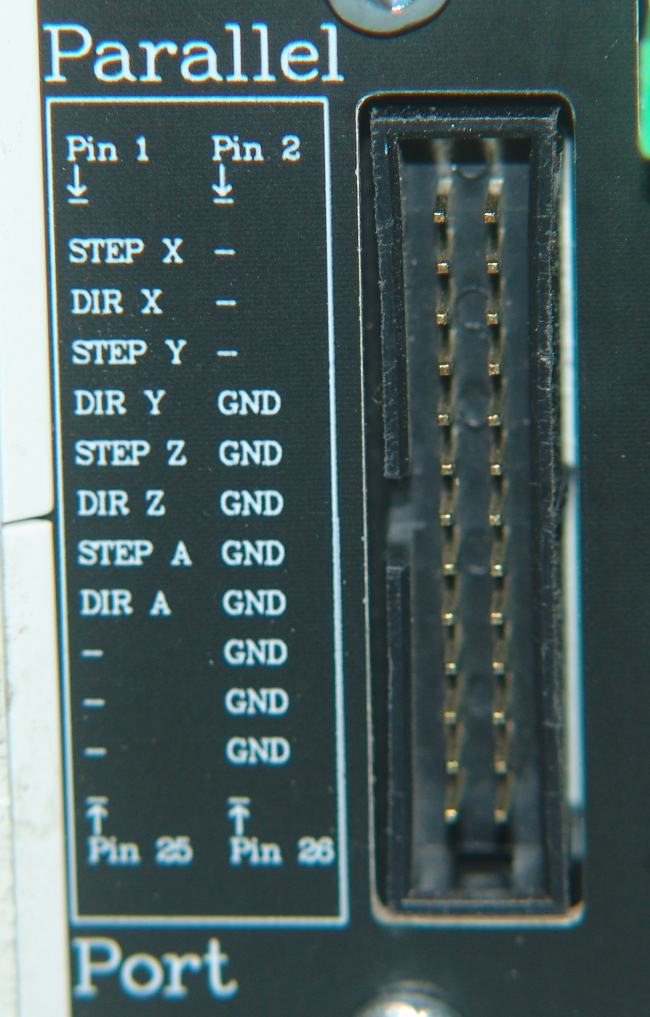

See picture for specific pinout on the IDC26 connector.

See schematic drawing for IDC26-DB25 pin correspondence as listed below:

The corresponding Parallel Port DB25 connected to a PC parallel port is a follows:

STEP X - Pin 2

DIR X - Pin 3

STEP Y - Pin 4

DIR Y - Pin 5

STEP Z - Pin 6

DIR Z - Pin 7

STEP A - Pin 8

DIR A - Pin 9

GND Pins 18-25

The DIR line need to be stable 200nS before and after the Rising (active high) edge of the STEP line.

The STEP line is of Active High (+) polarity.

Use the information above to properly set up the STEP/DIR parameters in the CAM software.

To gain access to the extra I/O from the signal port (for attaching limits switches, etc.), you can use an external breakout board.

The drive box plays NO role in processing other I/O such as Limit/Home/Stop/Probe inputs or other outputs.

IMPORTANT NOTES:

Dust can accumulate on the internal heatsinks and inside the fan components (clogging and thus stopping the fan), therefore keep the drive box in a DUST FREE ENVIRONMENT. For example, build an enclosure for the box using Furnace Filters. Accumulated dust inside can cause drive overheating or fan destruction leading to more heating issues, thus lowering the life of all of the components.

* Keep the drive box bottom up at least 1/2 inch to allow cooler air to be drawn in and warmer air to be expelled.

* Keep coolant, dust and chips away from the system. Small metallic “dust” and chips can easily be pulled in by a fan and deposited on the drive board, shorting it out!

* If you are using a vacuum system around the motor controller, it MUST be properly grounded to dissipate static build-up. This means the inside length of the vacuum hose has a flexible bare copper ground wire running the length and Earth Grounded at the vacuum motor end!

Do NOT connect or disconnect motors when the system is powered.

Do NOT place a fuse, switch, relay or circuit breaker between the motors and the drive box.

Do NOT connect scopes or any other test devices to the motor leads.

Shipping is with two USPS Medium Flat Rate Boxes: $17.05 X 2 = $34.10

USA Shipping only.

No international Shipping.