FAQs

1) How Do I wire Limit/Home switches to the 3/4 Axis Drive board

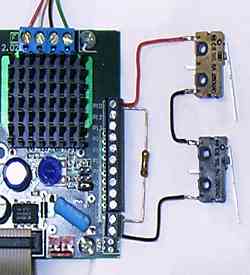

The drive board has nothing to do with switch inputs other than provide a place to make a connection to the unused parallel port I/O. These connections are made at the Black (4 axis Board) or Green (3 Axis board) 10-position screw terminal. How the extra I/O are used are determined by the software, and the type of switch being used. An example of a switch input can be seen here:

2) The drive can handle 2.5A/phase motors. There are 2 phase per motor, and 3 (or 4) motors per board. How can a single 5.0A/24VDC Power Supply handle all of this?

The switching action of the Xylotex controller plus the inductance of the stepper motor have a sort of transformer effect. Suppose the power supply is 24 V, but the motors are need 2.4 V at 2 amps for full torque. If the Xylotex is set to deliver 2A to the motor, it does deliver 2A average. But the power supply only has to deliver 0.2 A at 24V, or a little more. 0.2 A at 24 V (from the power supply) is the same amount of electrical energy as 2.0 A at 2.4 V (delivered to the motor), so there are no energy conservation laws being broken. But the power supply current is far less than the motor current. What actually happens is that the Xylotex draws current from the power supply about 10% of the time, and uses nothing the other 90% of the time. The peak current from the power supply is in fact about 2.0 A, but because of the duty cycle the average current is only 0.2 A. Average current determines the size of power supply needed. But the motor current averages 2.0 A all the time, so the motor develops full torque. The place where you need more current from the power supply is at higher motor speeds. As the motor runs faster, the winding current stays constant (because of the drive) but the voltage goes up, which requires more power. Since the power supply voltage remains constant, the power supply *current* increases in step with the motor *voltage*. So to run motors fast, particularly with more than one motor moving at once, you need more current.

3) What Software can I use with the Xylotex Drive?

The drives requires standard STEP and DIR signals. These signals are usually generated via CAM software programs running on a suitable PC with a parallel port. These CAM programs accept g-code files generated by CAD programs such as BobCad or Autocad. The Xylotex pinout requirements for the parallel port are: STEP X - Pin 2

DIR X - Pin 3

STEP Y - Pin 4

DIR Y - Pin 5

STEP Z - Pin 6

DIR Z - Pin 7

STEP A - Pin 8

DIR A - Pin 9

The DIR line need to be stable 200nS before and after the rising edge of the STEP line.

The following is a partial list of CAM software that will work with the Xylotex drive:

Mach3 - http://www.machsupport.com

TurboCNC - http://www.dakeng.com

LinuxCNC - http://www.linuxcnc.org/

KCam - http://www.kellyware.com

CNCPro - http://tech.groups.yahoo.com/group/CNCPro/

4) My PC does not have a Parallel Port. Can I use a USB-Printer adapter?

(1) No. The STEP and DIR signals need to have an even pulse train output. Normal USB-printer adapters are not real time and would provide a ragged pulse train. This would cause the motors to stall. You can use a Parallel Port PCI adapter if your PC has a PCI connector inside. Be sure the card matches the port type (PCI-e, -64, etc.).

(2) You can use an external pulse generator through a USB port. Devices like Smoothstepper or UC100 are external USB devices that can be used to interface between Mach3/4 and the drive box. Check with Mach3/4 and the hardware vendors for more information on these devices. Smoothstepper also makes an Ethernet connected Pulse Generator as well.

5) Are the drives opto isolated?

No. The 3 and 4 axis drive boards have no optoisolation on them. They do have R/C filtering and HCT541 logic buffering on them. The R/C filtering helps keep out spurious signal noise, while the logic buffer allows the drives to receive signals from green PCs that may have low voltage signals from the parallel port. Opto isolation becomes necessary in especially noisy environments or with voltages higher than the 3 and 4 axis drive boards use.

6) How do I add relays for coolant pumps or spindle?

You would need to take one of the parallel port outputs, and apply it to some sort or relay driver. SSR relays have built-in control, while mechanical relays will require an external relay driver. If you need relay control, an external break-out board with these capabilities is recommended.

7) Do I have to run all of the motors and/or drives?

No. Unused axes should be disabled, but the drive will not be harmed if you do not have motors plugged in. Never plug or unplug a motor with the drive powered up.

8) Can I use different motor sizes for each axis?

Yes, Each drive on a 3 or 4 axis drive board acts independently of the others. For example you can have the X and Y run 269 oz.in. motors while the Z axis runs a 425 oz.in. motor. You need to set the Vref for each drive according to its motor requirements.

9) Can I run two motors from one axis?

No. If you need to run 2 motors for an axis (i.e. two motors driving the gantry on a router), then you should slave two motors. For example with a 4 axis drive board, the A axis would be slaved to the Y axis signals. Software such as Mach3 will allow axis slaving.

10) Which motors will be best for my Sherline/Taig/X1/X2?

For higher pitch leadscrews like those found on the Sherline, Taig, and smaller SIEG machines, the 269 oz.in. motor is the better choice. It will give better high speed performance when compared to the 425 oz.in. motor.

11) Which motors would be best for my router?

If you are using high pitch leadscrews (15 to 20 tpi) then the 269s would be the recommended choice. If you are using lower pitch screws, like 5 tpi ballscrews, then the 425s would be the better choice. If you have ~10 tpi screws, the 269s will give better rapids, but lower low-speed torque. The 425s will give more low-speed torque, but slower rapids. The actual power from the drive board does not change (2.5A at 24VDC). The 425s are like a car running in low gear, the 269s are like running in higher gear (the power source -the cars engine - does not change significantly).

12) How do I set up the microstep settings?

The step settings headers are in the center of the board along with the ENA header. The drive ships with the ENA header jumpered. The other two pin sets used for step setting are not jumper, thus placing the drive in 1/8 step mode. To see how to set the step rate, look at this document: http://www.xylotex.com/StepSetting.pdf

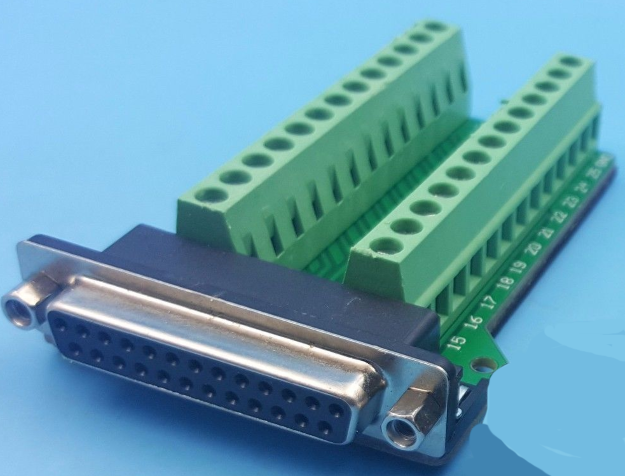

13) What are the pinouts for the unused parallel port I/O on the black screw terminal?

See the last page of the datasheet for the pinouts. For example, you will see the notation P10. This means that the corresponding terminal connects to DB25 Parallel port pin number 10 4 Axis Data Sheet: http://www.xylotex.com/XS3525V400.pdf 3 Axis Data Sheet: http://www.xylotex.com/XS3525V202.pdf

14) Can I run 6-wire motor with the Xylotex drive?

Yes, see the last page of the datasheet (see #13 above) for the half-winding and series winding diagrams. 6-wire motors rated above 3.5A should be run in series mode, while motors 3A or less should be run in half winding. In series mode you use from HALF the rated amperage (you are using twice the number of wire turns) of the unipolar mode (on up to rated current X .71). For half winding, you use the rated motor current.

15) What are the Stepper Motor Mounting dimensions?

Both the 269 oz.in. and the 425 oz.in. stepper motors have a Nema23 mounting faceplate. A drawing of the faceplate with dimensions can be found here: http://www.xylotex.com/images/Nema23.jpg

16) What are the manufacturer numbers of the motor & cable connectors used?

Description Molex Part#

Motor Crimp Connector 02-06-2103

Motor Plastic Shell 03-06-2044

Cable Crimp Connector 02-06-1103

Cable Plastic Shell 03-06-1044

Available from:

http://www.mouser.com

http://www.digikey.com

Cabling can be purchased from places like Home Depot. Get 4 conductor, 18 gauge, Stranded cabling.

The Crimp pins used are:AMP Part #:19212-0003-C available from http://www.digikey.com

17) What RPM can I get with your motors?

There is no real RPM rating for the motors. Unloaded they will spin very fast. All stepper motors loose torque as they go faster, and will have more torque at lower speeds. Your actual traverse rate in IPM (inches per minute) will depend on the mass and friction of the machine. Cutting rate will also depend on cutter sharpness, width and depth of cut, spindle speed, hardness of material, etc. When using 10 TPI screws with the 269s you can get between 50 and 75 IPM. When using the 425s you will get around a max. of 50 IPM, but with more lower speed torque. If you have 5 tpi screws, then you are better off with the 425s. With the 425s and 5 tpi screws on a smooth running machine you can get over 100 IPM. Your actual rapid speed will depend on the screws being used and the motor selected (as well as the dynamic of the actual machine).

18) The motors are rated at 2.8A, but the drive can only output a maximum of 2.5A?

You will not get full rating from the stepper motors since you can not go past 2.5A/phase with the drive. But, in most cases, you actually want something even lower than 2.5A The reason is that at higher step rates the current may not have time to build up to full level in the motor coils before the next step pulse comes in. This will mean a distorted power sine wave and rough motion. Using a lower Vref means the current can build up to the proper levels and produce a smooth sine wave to the motor coils. This helps minimize the distortion problem, which allows for smoother motor movements (the reason you want microstepping in the first place). The smoother motion allows more of the high speed torque to be delivered to your load rather than in to overcoming vibrations and oscillations. You will see lower slow speed torque at a lower Vref setting, but for most people the low speed torque produced is more than adequate to do the job.

19) What is all this about RoHS and not shipping to the EU ?

On July 1st, 2006, The EU started enforcing the RoHS law. RoHS stands for Reduction of Hazardous Substances. It restricts importation in to the EU of certain things, one of which is lead (Pb). Xylotex products are made with lead based solder, so are restricted from being imported in the the EU, thus Xylotex does not export to EU countries.

20) What are the Molex .1inch housing numbers?

Part type and Molex part #

2 Pin Housing 22-01-2027

4 Pin Housing 22-01-2047

5 Pin Housing 22-01-2057

9 Pin Housing 22-01-2097

10 Pin Housing 22-01-2107

The crimp terminals are 08-50-0114

These parts are available from http://www.digikey.com

21) What is the deal with Static Discharge and Grounding?

You can not ground the drive board to protect it from static discharge, you need to keep it away from static charges. For the most part, this means keeping it in an enclosure where static charges (fingers, hoses etc.) can not get to it. The more important thing is to keep static charges from getting to the drive board via the cabling/wiring. Vacuum (dust collection) hoses are a major source of static charges with wood working routers. There must be an exposed copper wire/cable (usually flexible braided copper - perhaps tin plated) running through the entire inside length of the vacuum tube where it will come out at the motor end and make contact earth ground. This earth ground would be the same as the round prong on the power cord, or the green wire inside the power cord. Ungrounded vacuum hoses can build up a large static charge (in the thousands of volts). This can easily pass through regular insulation (usually rated between 200 and 600 volts), and travel down through motor/signal cabling to the drive board which has an absolute maximum rating of 35VDC.

22) Is it OK to crank the motors manually?

Yes, turn off the power to the drive and crank them at manual speeds.

23) The red LED on the drive board glows dimly even after turning of the power to the drive.

The signals from the parallel port are back driving power in to the board. This is OK, and is not a problem

24) My motors sometimes run rough or even stall. What can I do.

You may be experiencing mid-band resonance. Take a look HERE

25) What can cause a board failure

Please read THIS page.

26) What Do I Need to Build a CNC Machine

Please read THIS page.

27) Help, I can not make Mach3 communicate with the drive box

First, try the drive box in autorun mode using the jumper wire shipped with it connected between pins 14 and 15 of the DB25 connector on the drive box at powerup. The drive box should make the motors move back and forth. This checks power to the drive box and motors. If this does not work, note whether the red power switch lights up, whether the fans run, and whether the motors -lock up-.

Second, Is the problem is with the parallel port address? Check the windows hardware system to make sure you have the proper address for the parallel port in the CNC software parameters. Do not use parallel port addresses off the internet. The address in the CNC parameters will be specific to your computer hardware.

Third, test the physical port. Use a multi-meter set for DC volts. Put the black lead on Pin 25 of the DB25 connector coming out of the PC. Put the red lead on Pin 3 (this is the X DIR pin) of the same connector and then note the voltage while jogging the X axis both forwards and backwards. It should change from a voltage of less than 1.0 volt to a voltage of greater than 3.0 volts (or visa versa). If this does not work, make sure that the jog keys for the X axis are setup properly in software. If this still does not work, try a simple g-code program that moves the X axis forward a couple of inches and then back. You should see a change. If it still does not work then there would appear to be a problem with the software communicating with the parallel port, or the parallel port itself is not working.

Fourth, Note that 64 bit Windows does not use the parallel port so will not work for the parallel port testing mentioned above.